Our production facilities

SACRED offers you five mixing and blending lines,

located on two production sites.

Our production methods

- 2 x lines for black compounds: 1 x tangential 100-litre line and 1 x Intermix K5 80-litre line, fully automated

- 3 x lines for colour compounds: 1 x Intermix K4 60-litre line and 2 x tangential 96-litre lines, fully automated

- 2 x continuous band printers

- 4 x batch-off units for plates and scalloped trims

- 2 x low-pressure filtration extrusion lines

- 5 x pellet machines for the production of compound granules

- 1 x Barwell for the production of blanks, according to your needs

- 2 x band batch-off units for plates and scalloped trims

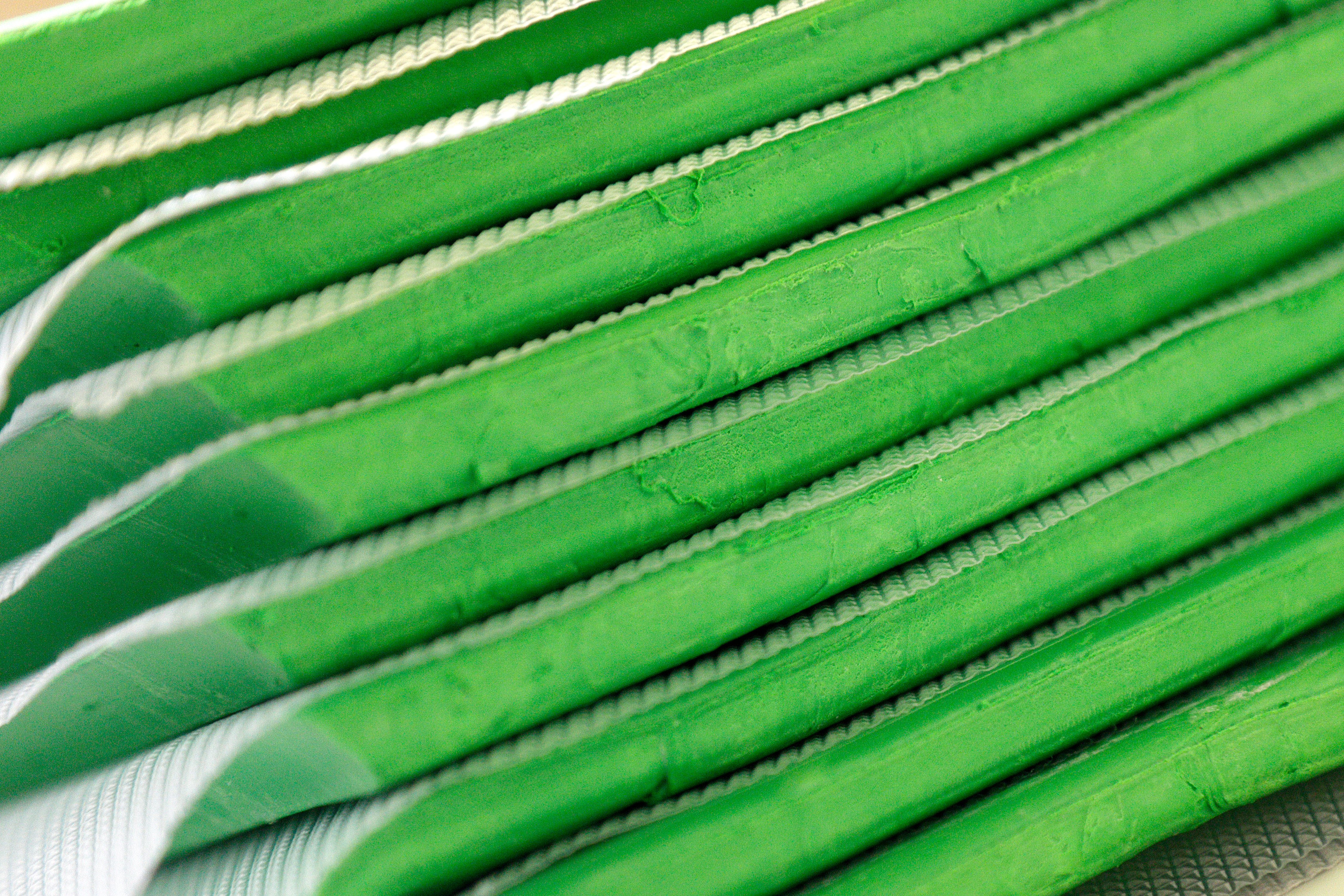

Product formats available

- Continuous strips in 100 kg or 350 kg boxes

- 80 x 120 cm plates on non-returnable pallets

- Filtered compound in strips or granules

- Granules in bags or boxes

- Weight or size blanks, depending on your needs

Un système de gestion de

production assisté par ordinateur

Our manufacturing facility is equipped with a centralised system to automatically control all weighing.

It prepares and validates all weighing in line with established tolerances. This system centralises the formulations and all the associated production parameters. The weighing of carbon black and oils is fully automated and they are injected directly into the mixer at the right time. Machine control can be determined by the temperature, the rotation speed of the rotors, the power consumption and the pressure on the piston.

We can supply ready-to-use compound delivered in various pack sizes to best suit your transformation processes (injection, compression, transfer, extrusion, calendaring or coating). We can organise whichever packaging format and transport method is most convenient for you. We have a varied and comprehensive stock of raw materials so we can quickly respond to your needs.

Our responsive and agile approach

means we can offer you troubleshooting

services in under 48 hours.