Research and development

SACRED has two fully equipped

development laboratories.

Two teams consisting of 10 engineers and technicians are on hand to help develop your formulations, validate your specifications and monitor production of your compounds.

Both laboratories are fully equipped with everything needed for producing prototype compounds and validating the various criteria in your specification.

We can develop and supply ready-to-use formulations made from all types of elastomers: NR, SBR, BR, IIR, NBR, NBR/PVC, HNBR, EPDM, CR, CSM, ECO, EVA, AEM and ACM, with the vulcanisation system best suited to your specification.

Our test facilities

All our equipment is regularly checked and calibrated in accordance with the manufacturers’ recommendations. Our teams receive the best possible training in the use of this equipment. These facilities allow us to independently test 95% of the most common requirements of different specifications.

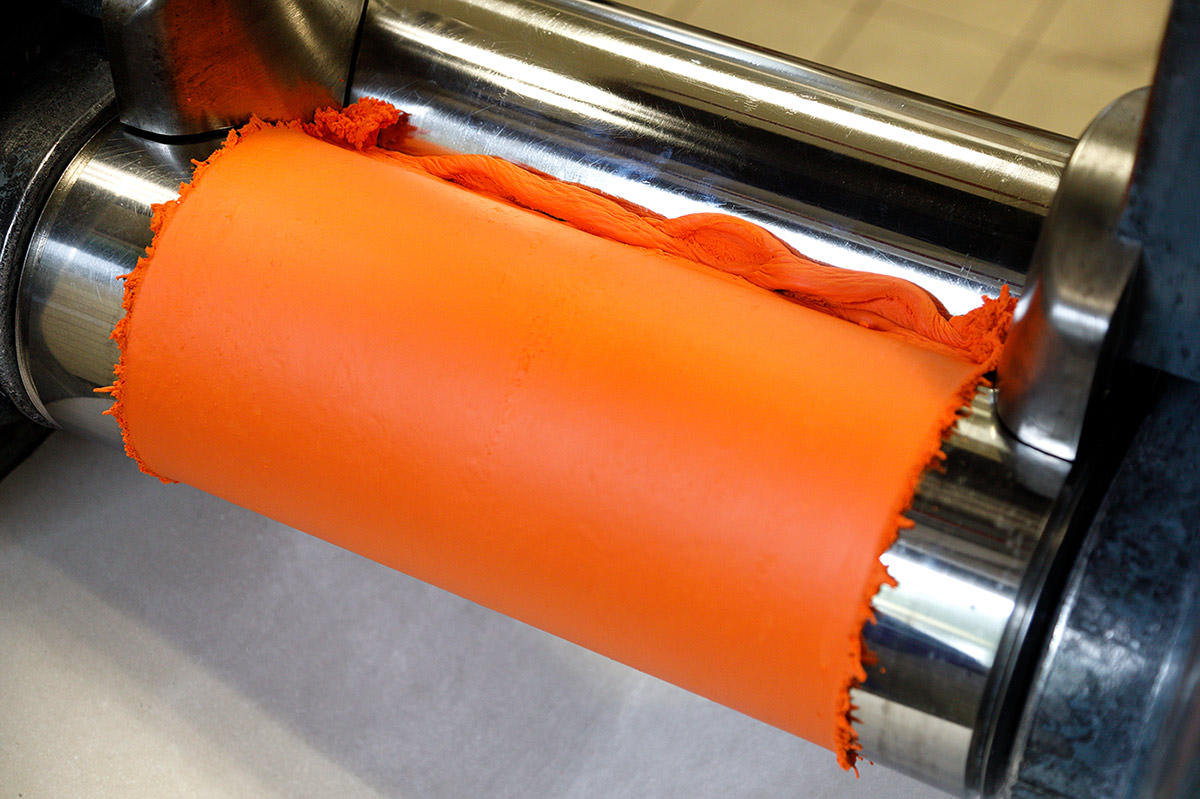

- 2 x 1 kg External cylinder prototypes

- 1 x 3 kg +1 x 2 kg Internal mixer prototypes

- 2 Moving Die Rheometers (MDR) and 2 MV2000 viscometers including Daisy software with calculations for rheological properties, ranges and envelope curves

- 2 x laboratory presses for compression moulding plates and plots between 150 and 200°C

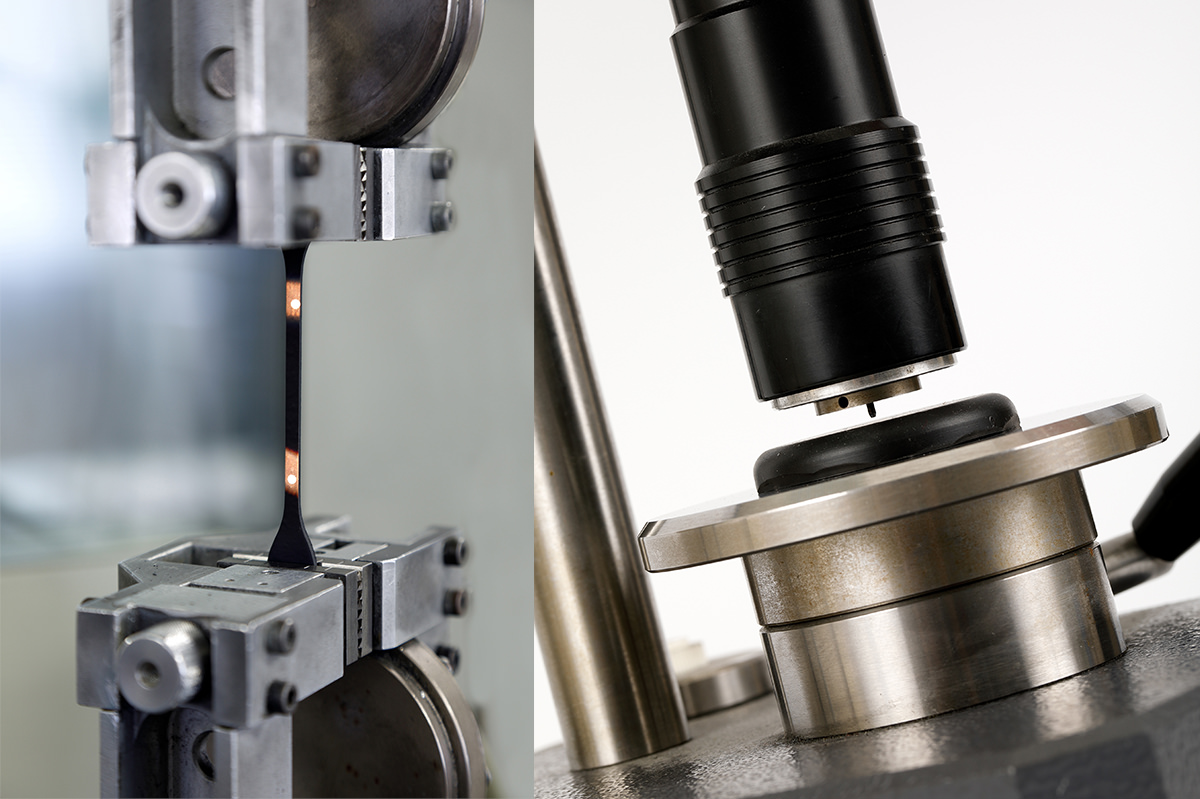

- Tensile testing for all sizes to ISO 37 and ISO 34 standards

- 2 x Electronic dynamometers with non-contact optical extensometers and hot/cold chamber (-50°C, +200°C)

- 15 x hot/cold ovens with the option of cycles (-50°C, +200°C) to ISO 3387 and ISO 188 standards

- Standardised fluids for accelerated ageing tests (fuels: A, B and C, oils: ASTM ,IRM , etc.) to ISO 23529, ISO 1817, ISO 2781 and ISO 2285 standards

- All-temperature determination of Rubber Compression Set, Rubber Tension Set and Stress Relaxation to: ISO 815, ISO 2285 and ISO 3384 standards respectively

- Standardised low-temperature tests (flexibility as per GEHMAN test, shrinkage temperature RT 10, low-temperature brittleness test as per brittle point) to ISO 1432, ISO 2921 and ISO 812 standards

- Standardised tests for ozone resistance to ISO 1431 and ASTM D 1149 standards

- Rebound tests to ISO 4662 standard

- Abrasion tests to ISO 4649 standard

- Measurement of electrical resistivity according to ASTM D 257 Standard

- Measurement of breakdown voltage to NF EN 60 243 Standard

- Dynamic tests and tests for fatigue resistance on MTS 810 according to your need

- Hardness testers: IRHD, micro IRHD, SHORE A, SHORE AM according to ISO 7619 and ISO 48 standard

- Tests for horizontal flammability in accordance with ISO 3795

- Karl Fischer equipment for moisture analysis

- Shore A ,Shore AM , IRHD and micro IRHD hardness testers.

SACRED can provide you with solutions tailored to your cost and competitive constraints

Our purchasing power enables us to negotiate the best prices for the raw materials needed to manufacture your compounds.

- Special compounds: we are able to manufacture formulas based on your own specific recommendations and develop formulations that meet your needs.

- Low-cost compounds:we use our competitiveness and efficiency to benefit our customers, so we can meet your expectations at the best price.

We can offer you all the colours of the rainbow!

Our responsive and agile approach means we can offer you troubleshooting services in under 48 hours.